Predictive Maintenance System with Graph

In an era where every gear's turn and every machine's heartbeat are critical to success, understanding and foreseeing potential glitches is not just a strategyâit's a necessity. From predicting potential failures to charting out an intricate web of dependencies, this article is your gateway to unlocking the future of maintenance efficiency.

What is a Predictive Maintenance System?

From a data analytics perspective, a predictive maintenance system is a system that checks the physical condition of equipment and accurately predicts the potential failure factors of various types of equipment. It also constructs a prediction model through data collection, analysis, and scientific management related to the equipment to improve problems. By addressing issues proactively, minimizing downtime, and preventing cost losses, our system ensures optimized performance and longevity for your equipment.

The traditional predictive maintenance system primarily relies on learning data patterns from time series databases, alerting the real-time monitoring system when anomalies are detected. While time series-based pattern analysis proves effective in predicting and handling errors to a certain degree, it falls short in determining causality - understanding the factors that lead to a failure. This limitation arises from the inability of these analytical techniques to consider equipment and equipment interactions comprehensively. To enhance predictive capabilities, capturing and analyzing the relationships between frequently occurring equipment failures is crucial. This approach effectively predicts failure factors by considering potential elements and understanding the intricate interplay between equipment components.

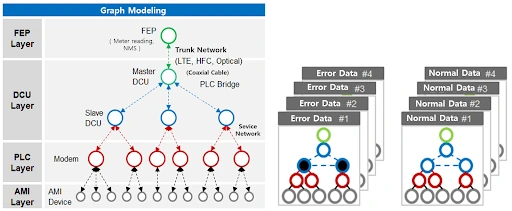

Using Graph Modeling in the Predictive Systems

The relationship among equipment can be shown in a graph, enabling the recording of failure patterns and facilitating the management and analysis of similar accident types. A foundational graph model applicable in a predictive maintenance system is the 'hierarchical structure model.' This model captures hierarchical relationships, where data from individual facilities feeds into the central monitoring system located in the central control room through the upper structure's data centralizer. This structure, commonly encountered in equipment systems, aligns seamlessly with a graph model featuring nodes and edges tailored to match the system's hierarchical nature. Through this representation, the model records the circuits and networks that connect equipment and highlights the interaction factors between two pieces of equipment.

Another applicable graph model is the 'Network Structure Model,' distinguished from the hierarchical structure model by permitting interaction between terminals. With the advent of the IoT (Internet of Things) era, there is a substantial increase in data generated by diverse equipment, emphasizing the demand for a predictive maintenance system capable of modeling these intricate relationships. The graph model effortlessly captures and models the connections within this data, empowering a graph-centric predictive maintenance system to explore and discern patterns between different pieces of equipment.

-

Capturing Circuit Connections and Equipment Interactions:

The predictive maintenance system can proficiently record and manage the interactions between equipment and their connecting circuits. These interactions are stored and documented at the edge-level in a graph-based predictive maintenance system. This feature is particularly noteworthy as the industry transitions from traditional hierarchical structures to IoT network configurations. The system's ability to 'model the relationship between equipment' aligns seamlessly with the evolving infrastructure.

-

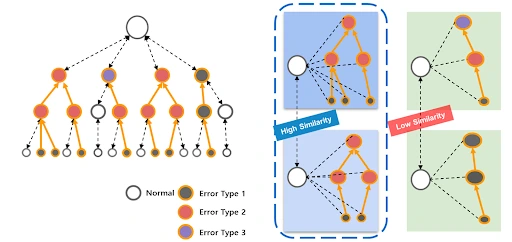

Recording Failure Patterns and Analyzing Similar Incidents:

Traditional predictive equipment solutions relied on preventing malfunctions and errors by analyzing patterns in time series data. However, the introduction of a graph-based approach allows for a more nuanced understanding. The system not only identifies patterns in accident types but also facilitates graph analysis to uncover potential factors that could lead to failure. This proactive analysis enables preventive measures to be implemented, mitigating potential issues before they escalate.

Predictive System, in summary, is not just about predicting potential glitches; it's about transforming prediction into prevention, ensuring a smoother and more resilient future for critical machinery and, consequently, the success of the organizations relying on them. If you want to create solutions based on the predictive system with graphs, speak to our consultant today for free!

Implementing a predictive maintenance system within a graph framework yields two key advantages: